Top Strategies for Maximizing Efficiency with Machine Shop Tools and Equipment in Modern Manufacturing

In today’s fast-paced manufacturing landscape, achieving optimal efficiency is paramount for staying competitive. According to a report by the National Association of Manufacturers, nearly 95% of manufacturers believe that advanced technologies, including cutting-edge machine shop tools and equipment, are crucial for enhancing productivity and operational efficiency. As companies increasingly pivot towards automation and data-driven methodologies, the role of machine shop tools and equipment becomes even more significant. By leveraging innovative strategies, manufacturers can not only streamline their processes but also reduce wastage and improve product quality. This blog will explore the top strategies for maximizing efficiency with machine shop tools and equipment, drawing insights from industry leaders and experts to provide practical tips that can be implemented in modern manufacturing settings.

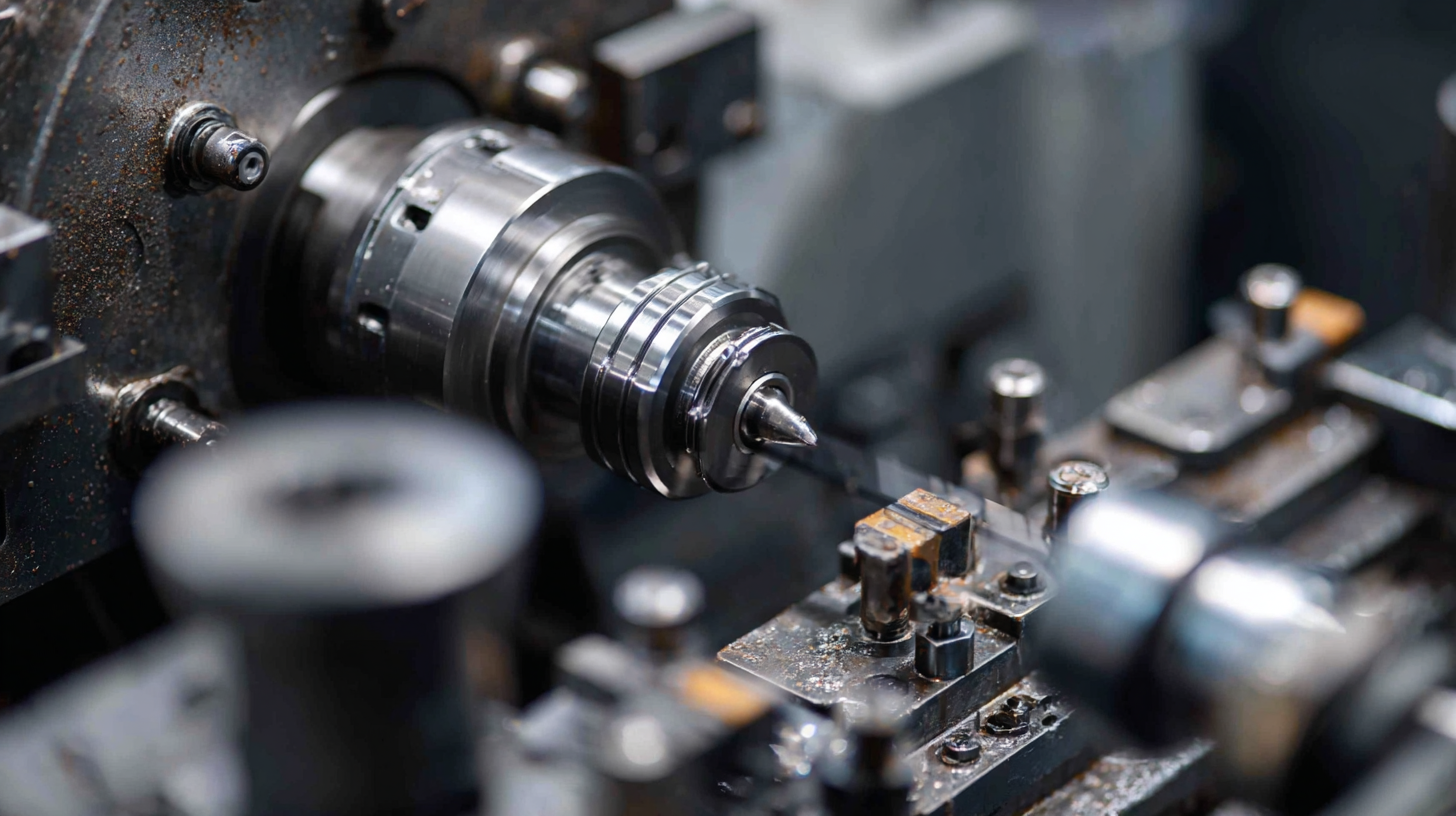

Understanding the Fundamentals of Machine Shop Tools and Equipment

In modern manufacturing, understanding the fundamentals of machine shop tools and equipment is essential for maximizing efficiency. Key to this is comprehending the types of tools available and their appropriate applications. For instance, milling tools come in various shapes and sizes, each designed for specific tasks. Studies have shown that utilizing the correct milling tool can reduce machining time by up to 25%, significantly boosting productivity. Machines like CNC lathes, on the other hand, offer precision and versatility, making them indispensable for intricate machining tasks.

Moreover, the effective programming of toolpaths is crucial for operational efficiency. Employing advanced software can streamline this process, allowing for 2D to 5-axis programming that caters to complex designs. Reports suggest that manufacturers adopting sophisticated toolpath programming see an average reduction in non-productive machine time of 30%, ultimately leading to quicker turnaround and improved overall efficiency. With the rise of digital twin technology, the ability to simulate machining processes is revolutionizing how resources are managed, further enhancing productivity while minimizing costs in the manufacturing landscape.

Productivity Metrics of Machine Shop Tools

This chart illustrates the efficiency of various machine shop tools used in modern manufacturing, highlighting the average productivity rate measured in units produced per hour.

Essential Maintenance Practices for Enhanced Tool Longevity

Maintaining machine shop tools and equipment is crucial for enhancing their longevity and optimizing manufacturing efficiency. Regular maintenance practices, such as routine inspections and cleaning, can identify potential issues before they escalate into major problems. For instance, lubricating moving parts reduces friction, preventing wear and tear, while ensuring that tools remain operational for longer periods. Additionally, keeping tools free from debris and conductive dust can significantly decrease the risk of electrical failures and other mechanical disruptions.

Another essential practice is calibration, which ensures that tools are operating within specified parameters. Regularly calibrating machinery not only improves accuracy but also extends the life of the equipment by reducing the strain caused by improper settings. Training personnel in proper usage and maintenance techniques fosters a culture of care, where each employee understands the impact of their work on the tools' longevity. By implementing these essential maintenance practices, manufacturers can safeguard their investments and maintain a high level of productivity in a competitive environment.

Top Strategies for Maximizing Efficiency with Machine Shop Tools and Equipment in Modern Manufacturing - Essential Maintenance Practices for Enhanced Tool Longevity

| Strategy | Description | Frequency | Expected Result |

|---|---|---|---|

| Regular Tool Inspection | Conduct visual inspections and functional tests to identify wear. | Weekly | Preventative maintenance and extended tool life. |

| Lubrication Practices | Apply appropriate lubricants to reduce friction and wear. | Biweekly | Improved performance and reduced maintenance costs. |

| Proper Storage of Tools | Store tools in a dry place to prevent rust and damage. | Daily | Increased longevity and reduced replacement costs. |

| Calibration of Equipment | Ensure all tools are calibrated to maintain precision. | Monthly | Higher accuracy and reduction in error rates. |

| Training for Operators | Provide ongoing training on best practices for tool use. | Quarterly | Enhanced skill set and operational efficiency. |

Integrating Automation for Increased Productivity in Manufacturing

Integrating automation in machine shops can significantly boost productivity and efficiency in modern manufacturing environments. According to a report by the International Federation of Robotics, the installation of industrial robots increased globally by 12% in 2021, illustrating the growing emphasis on automation in manufacturing processes. By adopting automated tools and equipment, manufacturers can enhance precision, shorten production times, and reduce operational costs.

To maximize the benefits of automation, businesses should consider implementing predictive maintenance strategies. This approach not only minimizes unexpected downtimes but also extends the lifespan of machinery. For instance, utilizing sensors and IoT technologies can provide real-time data about equipment performance, allowing for timely interventions.

Moreover, training employees to work alongside automated systems is critical. A report by McKinsey states that 60% of occupations could see 30% or more of their activities automated by 2030. Therefore, reskilling and upskilling the workforce can help workers adapt, thereby maintaining a balance between automated production and human oversight. Embracing these strategies ensures that manufacturers remain competitive in a rapidly evolving marketplace.

Techniques to Optimize Tool Selection and Usage

In modern manufacturing, optimizing tool selection and usage is crucial for maximizing efficiency in machine shops. Studies indicate that the effective allocation of resources can enhance productivity by up to 20%. One of the key strategies is to implement a systematic approach to tools selection based on the specific tasks at hand. By utilizing data analytics, manufacturers can evaluate the performance of various tools and establish benchmarks for optimal usage. Reports reveal that companies adopting data-driven decision-making in tool management significantly reduce waste, thus increasing overall operational efficiency.

Additionally, embracing technology such as automation and real-time monitoring can further refine tool usage. For instance, when machine tools are integrated with Internet of Things (IoT) capabilities, operators gain insights into their performance and can predict maintenance needs before they disrupt operations. A recent survey highlighted that organizations employing IoT in their machine shops saw a 30% reduction in downtime and a dramatic improvement in workflow efficiency. As the manufacturing landscape evolves, adopting advanced techniques for tool optimization will remain essential in driving productivity and remaining competitive.

Data-Driven Strategies for Monitoring and Improving Efficiency

In today’s manufacturing landscape, data-driven strategies are crucial for monitoring and improving the efficiency of machine shop tools and equipment. The implementation of advanced data analytics allows manufacturers to gain valuable insights into performance metrics and operational bottlenecks. According to a study by Deloitte, companies that leverage data analytics see an increase in productivity by up to 20% as they can make more informed decisions and optimize their processes more effectively.

Real-time monitoring systems play a pivotal role in this efficiency enhancement, as they enable manufacturers to track machine performance continuously. A report from McKinsey highlights that predictive maintenance, powered by data analytics, can reduce equipment downtime by 30-50%. By utilizing tools like IoT sensors and machine learning algorithms, manufacturers can anticipate potential failures, schedule timely maintenance, and ultimately extend the life of their machinery.

Additionally, employing data visualization techniques facilitates clearer communication of insights across teams. A recent survey by the Manufacturing Institute reveals that companies embracing data-driven decision-making report a 12% faster response to market changes. This agility not only improves operational efficiency but also enhances a manufacturer’s competitive edge in a rapidly evolving market.